Cutting metal with a jigsaw demands precision, and selecting the appropriate blade is paramount to achieving clean and efficient results.

In this comprehensive guide, we’ll explore which jigsaw blade to use for metal, providing insights into their compositions, advantages, and applications to empower you in your metalworking projects.

Which Jigsaw Blade To Use For Metal?

Bi-Metal Blades:

- Composition: Bi-metal blades combine high-speed steel (HSS) for the teeth and a flexible spring steel for the body.

- Advantages: Known for durability and flexibility, bi-metal blades excel in cutting through a range of metals, including steel, aluminum, and non-ferrous metals.

- Applications: Versatile enough to handle thin and thick metal sheets, making them a go-to choice for various metalworking applications.

Tungsten Carbide Blades:

- Composition: Tungsten carbide blades feature teeth made from tungsten carbide particles.

- Advantages: Renowned for hardness and heat resistance, tungsten carbide blades are ideal for cutting hard metals, such as stainless steel.

- Applications: Suited for tasks involving thick and hard metals, making them an excellent choice for precision metal fabrication.

High-Speed Steel (HSS) Blades:

- Composition: HSS blades are made from a type of tool steel designed to withstand high temperatures.

- Advantages: Effective for cutting thin metal sheets, HSS blades are often more budget-friendly compared to bi-metal or tungsten carbide blades.

- Applications: Suitable for cutting soft metals like aluminum and thin steel, making them versatile for various metalworking projects.

Carbide Grit Blades:

- Composition: Carbide grit blades feature a coarse grit edge made from tungsten carbide particles.

- Advantages: Specifically designed for cutting through abrasive materials, carbide grit blades are suitable for tasks involving metal with embedded materials, such as nails or screws.

- Applications: Ideal for tackling metalwork projects where the material may contain abrasive elements.

Diamond Grit Blades:

- Composition: Diamond grit blades boast a cutting edge coated with diamond particles.

- Advantages: Recognized for their hardness, diamond grit blades excel in cutting hard and abrasive materials, including certain metals.

- Applications: Effective for tasks requiring precision in cutting through hard metals, ceramics, and other challenging materials.

Considerations for Selection:

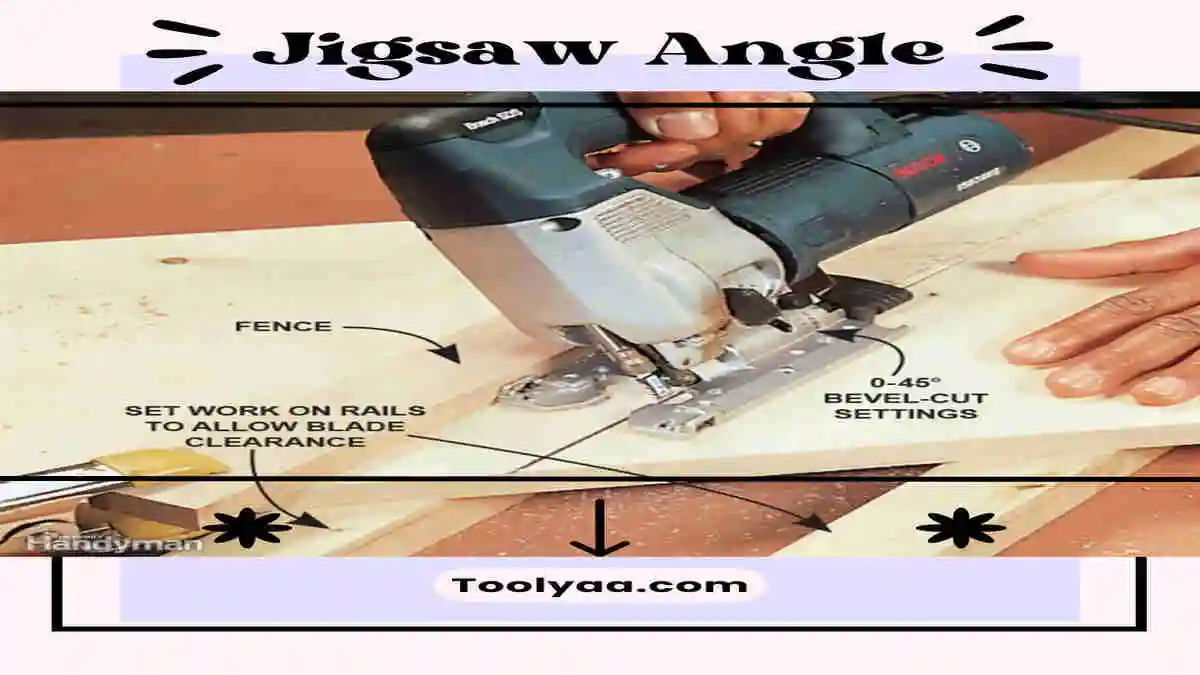

- Metal Thickness: Tailor your blade choice to the thickness of the metal you’re cutting. Different blade types are optimized for various thickness ranges.

- Project Requirements: Assess the specific requirements of your metalworking project. Whether it involves intricate patterns or straight cuts, choosing a blade that aligns with your project’s needs is crucial.

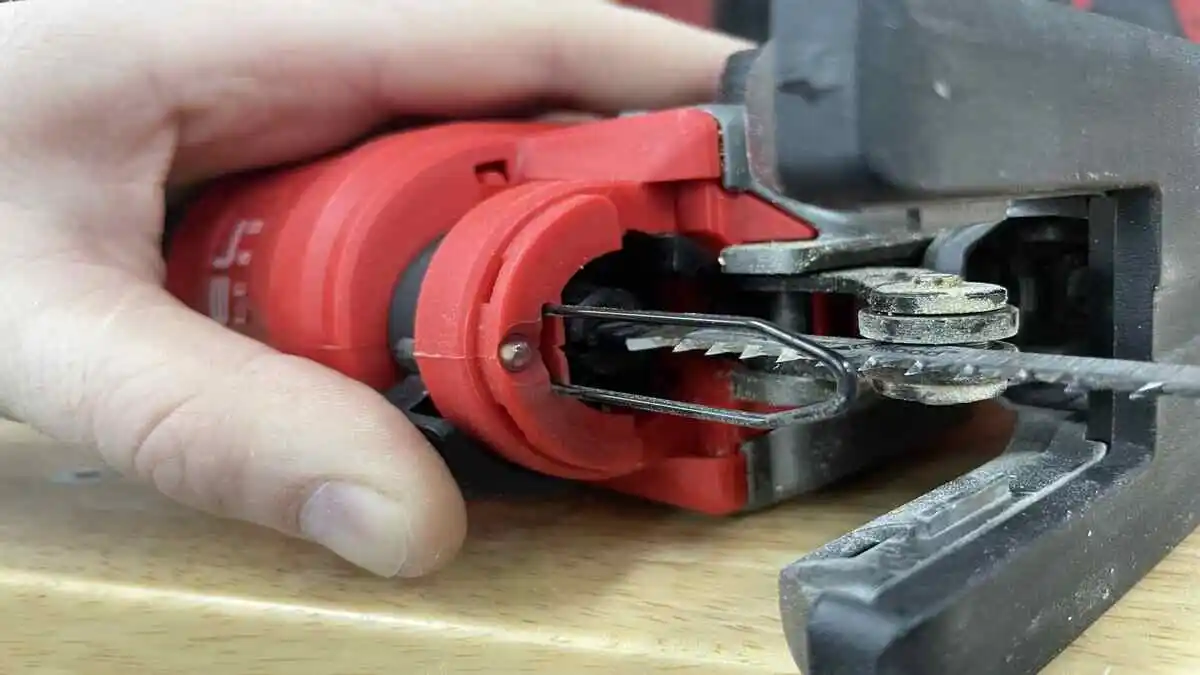

- Jigsaw Compatibility: Ensure the selected jigsaw blade is compatible with your jigsaw model. The right pairing of blade type and jigsaw guarantees seamless operation and optimal results.

Conclusion:

Selecting the right jigsaw blade for cutting metal is a nuanced decision that hinges on the type and thickness of the metal, as well as the specific demands of your project.

Armed with this knowledge, you can confidently embark on metalworking endeavors, achieving clean, precise, and professional-looking cuts with your jigsaw. Always prioritize safety, wear appropriate protective gear, and let the chosen blade be your trusted ally in crafting exceptional metal pieces.